Industry 4.0 Condition Monitoring

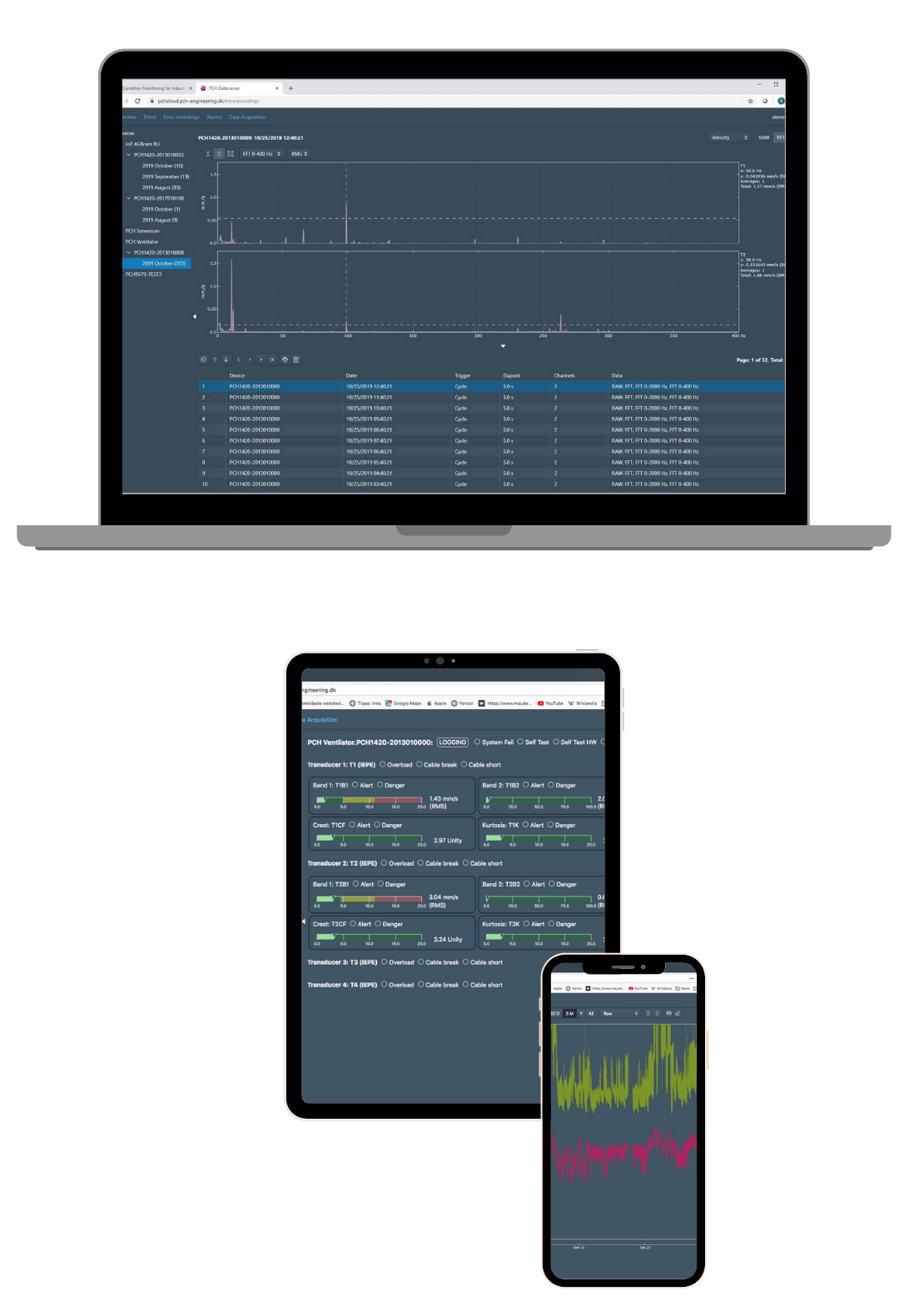

Get online, real-time vibration data for equipment performance optimisation and OEM services

Do you want to offer IIoT-ready equipment without draining your profits?

As smart factory technologies are sweeping across industries, and customer demand for IIoT functionality increases, original equipment manufacturers have to stay one step ahead of the development or risk falling behind their competitors.

Now, you can fit your OEM machine products with traditional, real-time vibration monitoring with the added feature of cloud storage for remote vibration data analysis.

Harness the full potential of Equipment as a Service by applying the extensive vibration data to performance optimisation, predictive maintenance, advanced condition monitoring, remote consultancy services and more.

Select from our range of sturdy, affordable, IIoT-ready vibration monitors and sensors. There is one for any budget.

PCH vibration monitors provide local safety in the form of alarms and shut-down functions and gather data for FFT analysis and trend mining.

With vibration data from your customers' equipment in real time, you get valuable information about machine performance to help you perfect your product design.

The vibration monitors can be pre-configured to your specific equipment. You receive monitors ready for mounting with no further adjustments required.

The vibration data is encrypted and uploaded through an Internet connection to a cloud database of your choice. You retain full ownership of data at all times.

The PCH Cloud solution uses open API formats to make integration with your existing monitoring solutions and edge computing simple and seamless.

Contact one of our expert consultants for more information on how the PCH Cloud Solution can help protect your machinery.

Total Cost of Ownership (TCO) is an increasingly important parameter for customers purchasing industrial equipment.

TCO includes not only the cost of purchasing the equipment, but also costs such as maintenance, spare parts, repair costs etc.

Adding IIoT functionality to your equipment may increase the initial investment.

However, by collecting and remotely analysing the extensive vibration data from your customers you can offer services such as predictive maintenance that will lower the Total Cost of Ownership (TCO) of your equipment and give you a competitive advantage.

The more data you can collect when producing prototypes and null-series machinery, the easier your troubleshooting analysis and problem solving becomes. Reliable data can also help you define reasonable warranties before you release your product to the market.

With PCH Cloud and the PCH hardware, the machine data is easily stored and easily shared among your engineers. You retain ownership of the data, which is encrypted and stored safely on our AWS servers or a database of your choice.

With the PCH vibration monitors, your customers will get the 4-20 mAs or alarm relays to which they are accustomed, and you get all the enhanced data simultaneously.

Contact us for further information.

With the PCH EtherBridge IoT, you can integrate seamlessly with a wide array of IIoT edge computers, ensuring a reliable and efficient communication pathway.

The PCH EtherBridge IoT works as an edge device and transfers critical, real-time process and vibration data from your client’s rotating machinery to your edge computer for immediate processing.

The PCH EtherBridge IoT collects vibration, temperature and pressure data from PCH sensors and monitors and transfers it to a designated folder on your edge computer for easy remote or local access.

The solution supports easy scripting through the rich and documented REST API to a wide variety of operating systems, including but not limited to:

Don’t see your preferred operating system on the list? Contact us:

With edge computing, you can process vibration data closer to where timely insights are most urgently needed.

An edge computer functions as the edge gateway, transferring processed data either to your own cloud or to a local server for added IT security.

In Industrial IoT monitoring, edge computing also enables your clients to use digital twins in their predictive maintenance strategy and make timely, well-informed maintenance decisions.

Proper maintenance, in turn, helps ensure reliable operation of your industrial equipment and extends machine life, helping to bring down the total cost of ownership and adding positively to your OEM offering.

PCH Engineering A/S: Sales

Connect with us on LinkedIn.

© Copyright 2020 PCH Engineering A/S