Remote vibration monitoring for service providers

Are you looking for a cost-effective solution to help you meet your clients' growing demand for increased machine performance, uptime, and profitability?

PCH Cloud is an online condition monitoring solution that enables you to monitor multiple assets with permanently mounted sensors and access to real-time vibration data online for vibration analysis, diagnostics and maintenance purposes - all from the comfort of your office.

Select from our range of sturdy, affordable, IIoT-ready vibration monitors and sensors. There is one for any budget.

PCH vibration monitors provide local safety in the form of alarms and shut-down functions and gather data for FFT analysis and trend mining.

With online access to vibration data in real time, you can safely diagnose asset conditions and schedule maintenance remotely.

With the IoT-compatible PCH 1420 vibration monitor with buffered outputs, you can extract raw data on site even when the permanent sensors are mounted in hard to reach places.

The vibration data is encrypted and uploaded through an Internet connection to a cloud database of your choice. You can easily share selected data with your clients - or they with you.

The PCH Cloud solution uses open API formats to make integration with your existing control and monitoring solutions simple and seamless.

Contact one of our expert consultants for more information on how the PCH Cloud Solution can help you provide even better service.

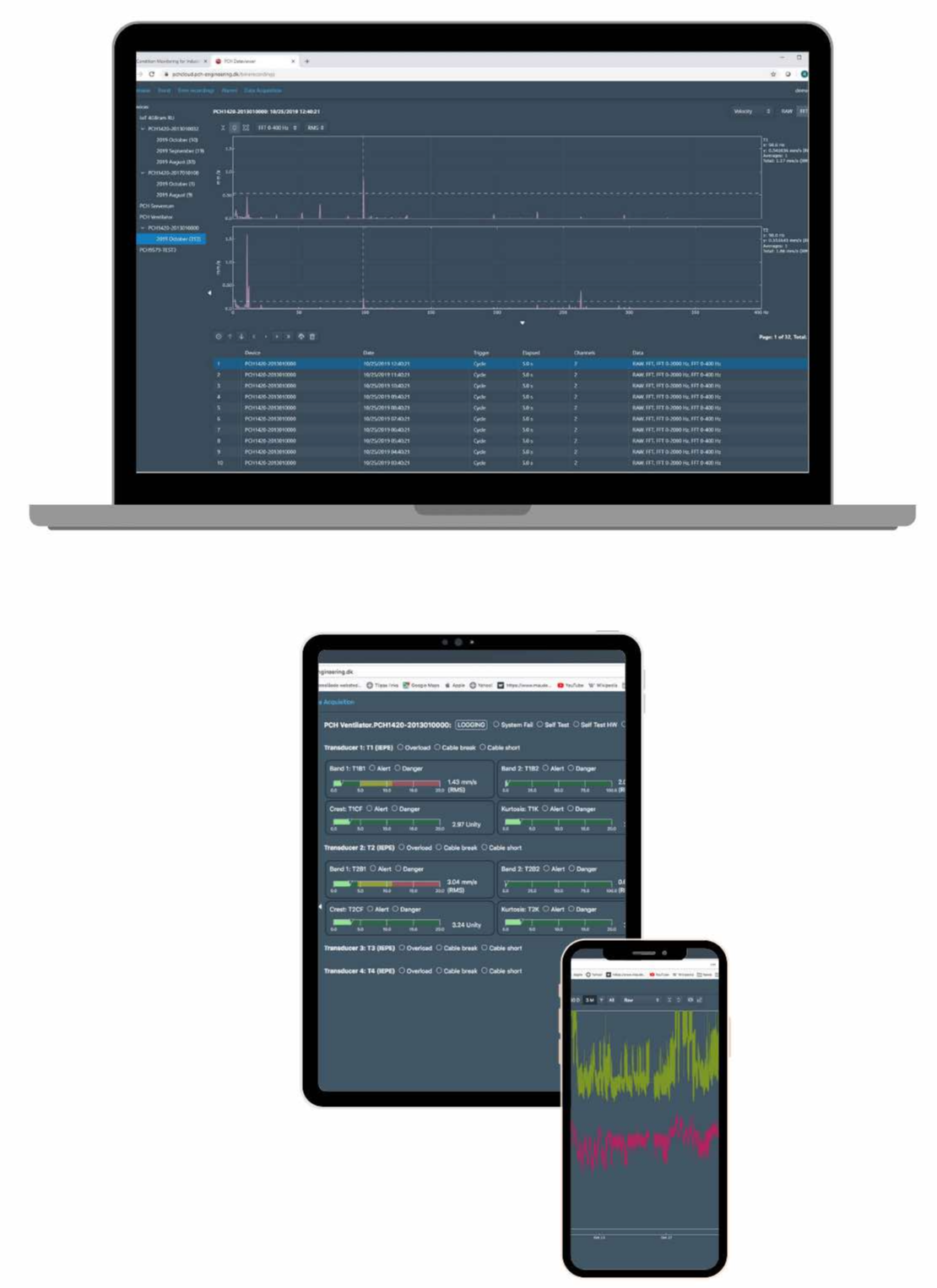

Vibration data is stored in the cloud. This allows your staff to access vibration data and data visualisations from any device with an internet connection - be it a laptop, a tablet or a smartphone.

When installing the PCH monitoring equipment on your clients' assets, you retain full control of the vibration data. You decide what data access to grant the customer and which data to share with your customer.

If your client owns the equipment, they can easily share all vibration data with you.

The online user interface provides various data visualisations, which you can use to illustrate your analysis and diagnosis in your customer reports.

In other words, you can reduce the number of service visits to each client while providing the same level of service and safety.

The user interface can be accessed from any smartphone or tablet, allowing your maintenance staff and/or vibration analysts to easily view vibration data from a particular machine for quick, on-site asset health checks, troubleshooting and vibration analysis.

Just scan the QR code on the machine to see all its data visualisations.

Seeing this page on your phone? Tab here to access the PCH Cloud user interface.

PCH Engineering A/S: Sales

Connect with us on LinkedIn.

© Copyright 2020 PCH Engineering A/S