Industry 4.0 Condition Monitoring

Improve machine performance and prolong machine life with PCH Cloud

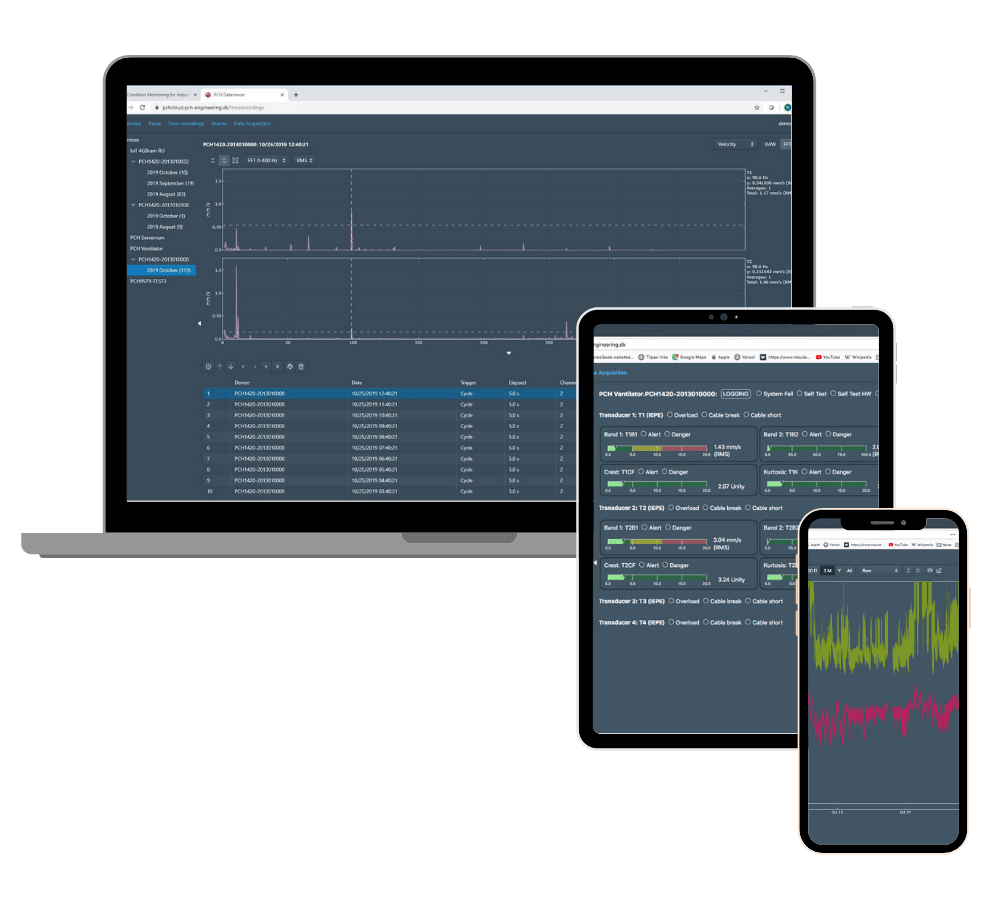

The PCH Cloud vibration monitoring solution with online IIoT functionality is the perfect tool for companies looking to develop a predictive maintenance strategy and improve machine performance and production throughput.

It is the first condition monitoring solution to provide you with essential, real-time vibration and process data, while allowing you to store and analyse machine condition data online.

In just one simple solution, you get local machine safety and remote data access.

The built-in warning, alarm and shut-down functions of the IoT-ready PCH vibration monitors protect your machinery and staff from machine damage 24/7.

With vibration data being stored in the cloud, your data scientists and maintenance team can handle Big Data integration and analysis remotely.

Vibration data in real time helps you and your maintenance team improve machine performance for each individual piece of rotating equipment.

All vibration data collected by the PCH Cloud vibration monitors is stored in a cloud database of your choice. You retain ownership of the vibration data at all times.

The vibration monitors come with built-in 4-20 mA outputs so you can easily transfer trend data to your SCADA or PLC solution using standard communication protocols.

The Iot-ready PCH Cloud vibration monitoring solution is a simple, cost-effective way to ensure that your plant can reap the benefits of Industry 4.0 technology.

Contact one of our expert consultants for more information on how the PCH Cloud Solution can help protect your machinery.

The PCH Cloud monitoring devices store real-time trend performance data online in a cloud database of your choice.

This allows your data scientists and maintenance team to access and analyse vibration data remotely from any location and any device.

With the data insights provided by the PCH vibration monitors, you can schedule maintenance based on the actual condition of each individual piece of equipment.

You avoid unplanned downtime of critical machinery and keep a stable production throughput without wasting money on unnecessary preventive maintenance.

Your most essential and costly assets, such as ID and HVAC fans, decanters, turbines, rotary atomisers, boiler feedwater pumps (BFWP) etc., require protection by an online protection system.

With the PCH IIoT solution, you obtain online, SIL 2-compliant protection as well as enhanced condition monitoring data that can be processed by your own data analytics software.

Contact us today for a discussion of your requirements.

PCH Engineering A/S: Sales

Connect with us on LinkedIn.

© Copyright 2020 PCH Engineering A/S