Industry 4.0 Condition Monitoring

Find answers to the most frequently asked questions about PCH Cloud here

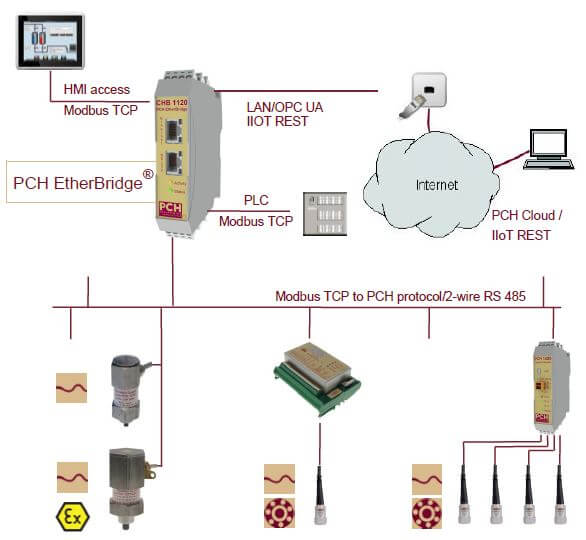

With the PCH Cloud Vibration Monitoring Solution, you get an IIoT platform (REST) that delivers vibration data from PCH monitors to an online database (either our AWS database or a database of your own choosing).

The PCH vibration monitors collect data from your machinery and export it through the LAN connection in the EtherBridge module to a cloud database of your choosing. You can use our AWS EC2 database or your own AWS storage medium.

You can now visualise the data online using the PCH Vibration Studio software or your own database interface.

There is no need for heavy investments in new Industry 4.0 machinery and production equipment with the PCH Cloud solution.

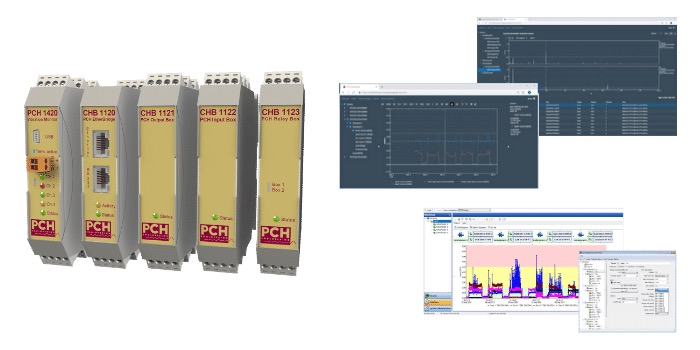

If your machinery is already mounted with one of the compatible PCH vibration monitors (PCH 1073, 1272, 1277 or 1420), you simply add an EtherBridge module to get the full IoT functionality.

If not, the PCH vibration sensors and monitors can easily be retrofitted to your machinery – regardless of its age. All you need to get started are PCH vibration sensors and monitors, a PCH EtherBridge module and an Internet connection.

In other words, the PCH Cloud solution is a simple, safe and cost-efficient way to make your machinery ready for Industry 4.0.

The IIoT solution can be added to the following range of PCH monitoring installations:

PCH 1232 (4-20 mA, 2 relays, Modbus RTU)

PCH 1232 (4-20 mA, 2 relays, Modbus RTU)

PCH 1420 (4-20 mA, SIL 2, relay outputs)

PCH 1420 (4-20 mA, SIL 2, relay outputs)

To collect the most extensive data for your trend analyses, we recommend that you use the PCH 1420 4-channel vibration monitor. If you already have PCH 1420 monitors installed, these can be connected to the IIoT platform via an EtherBridge module to give you all the benefits of the IIoT technology while maintaining your local machine safety.

We are happy to help you select the vibration monitoring solution to suit your need.

You do. Always.

We want to give you a flexible solution that can be adapted to your needs and existing systems, e.g. AWS IoT Core. That is why our IIoT solution is an open platform based on integration to other systems.

You retain ownership of the data collected by the vibration sensors, and you choose where to store it and how to analyse it.

All of the PCH vibration monitors mentioned above can be connected to a cloud database of your choice.

You can either store it in our cloud services. They run on AWS cloud servers (AWS EC2), and data is encrypted and stored in our PCH Cloud.

Or you can store it on your own storage medium. We integrate with the following 3rd party time series databases:

Whichever storage solution you choose, you retain ownership of your data at all times.

It is quick and simple to start using the data visualisation and storage tools of the PCH Cloud solution. The web application can be accessed online from any device anywhere. In other words, no installation of software is required.

Once you have your PCH EtherBridge IIoT Module, you can be up and running in approximately 10 minutes.

Here is how it works:

We use standard, open API formats such as Backend Interface, Devicemanager Interface and Usermanager Interface. To download these formats, check out our information for data scientists here.

Our data specialists can also design a solution to suit your data requirements.

Give us a call to learn more about customised formats.

If not, we are happy to help with any questions about the PCH Cloud Solution.

PCH Engineering A/S: Sales

Connect with us on LinkedIn.

© Copyright 2020 PCH Engineering A/S