Industry 4.0 Condition Monitoring

Easily include real-time vibration data in your condition monitoring program

without compromising on local safety

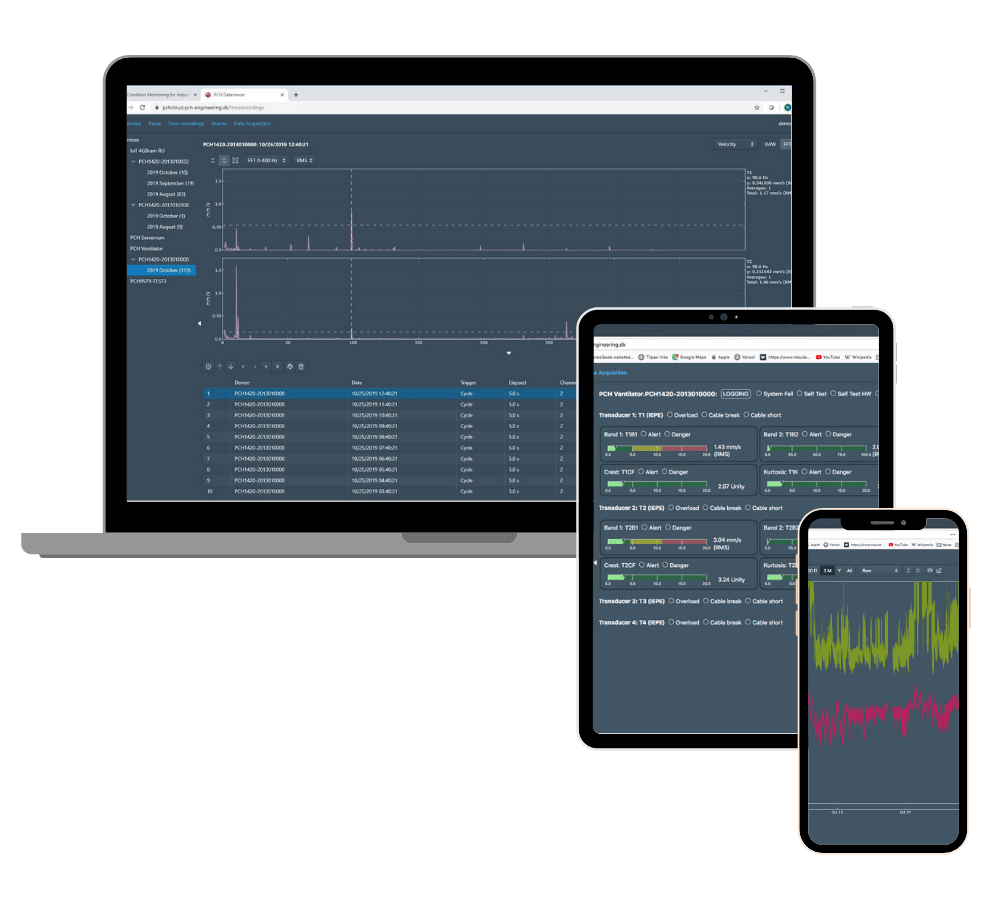

Access your condition monitoring data anywhere from any smart device.

Store data safely in an online database or transfer it to an edge computer or local server of your choice.

Monitor machinery in real time and correct faults promptly when needed.

Safety relays, alarms and shut-down functions provide on-site safety.

Get started with condition monitoring with a solution that grows with your business. This simple, plug'n'play vibration monitoring solution can be retrofitted to one or several machines, and data is easily shared with your in-house or external vibration specialists.

Prevent machine breakdowns through predictive maintenance and enhance local safety at your plant with a customised vibration monitoring solution that is easily integrated with your existing condition monitoring program or SCADA system.

Enhance machine safety and customer service with this low-cost vibration monitoring solution that integrates easily with your existing control and surveillance solutions. Store vibration data in your own cloud database and retain full ownership of data at all times.

The vibration sensors monitor the condition of your machinery 24/7 and alert you to issues that may result in damage.

Local alarms, safety relays and shutdown functions protect your machinery and your staff.

Predict the need for maintenance based on the condition of each piece of machinery. You avoid unnecessary service at set intervals.

By protecting critical machinery, you avoid unscheduled production stops due to machine breakdowns.

A consistent production throughput allows you to serve your customers effectively.

With online data access and cloud storage you are ready for the challenges and benefits of Industry 4.0.

The condition monitoring project has yielded positive results already. We recently managed to avoid a breakdown […]. We corrected the fault, and production continued as planned.

Jesper Haugaard, Vice President, EMA Operations, Novozymes A/SPCH Cloud is based on the PCH Link Concept, the popular modular vibration monitoring system designed by PCH Engineering.

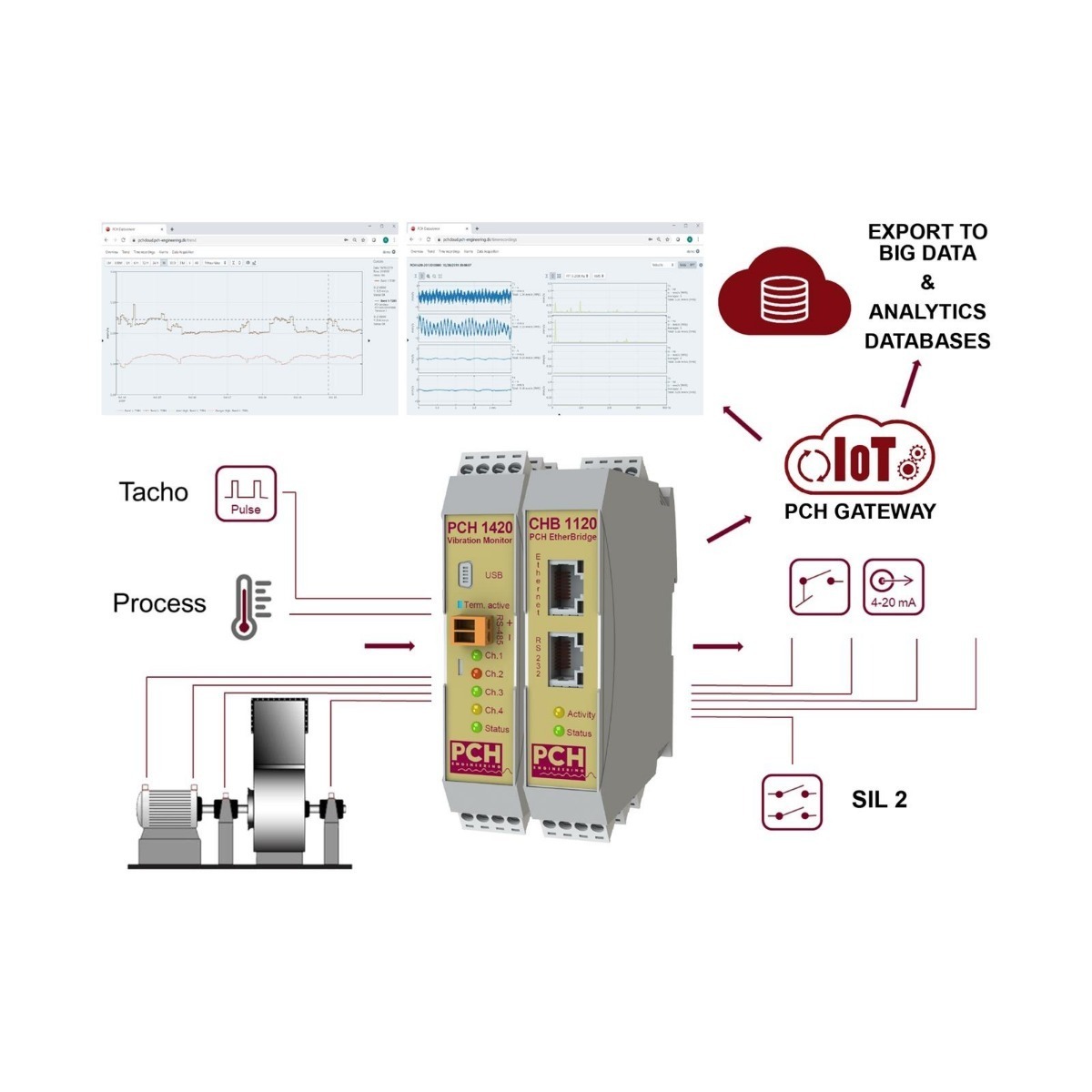

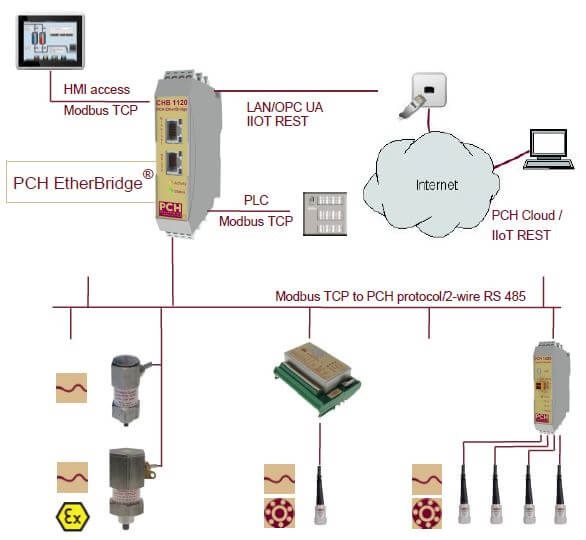

Combine any number of PCH monitors with an EtherBridge module for an IoT monitoring solution customised to your requirements.

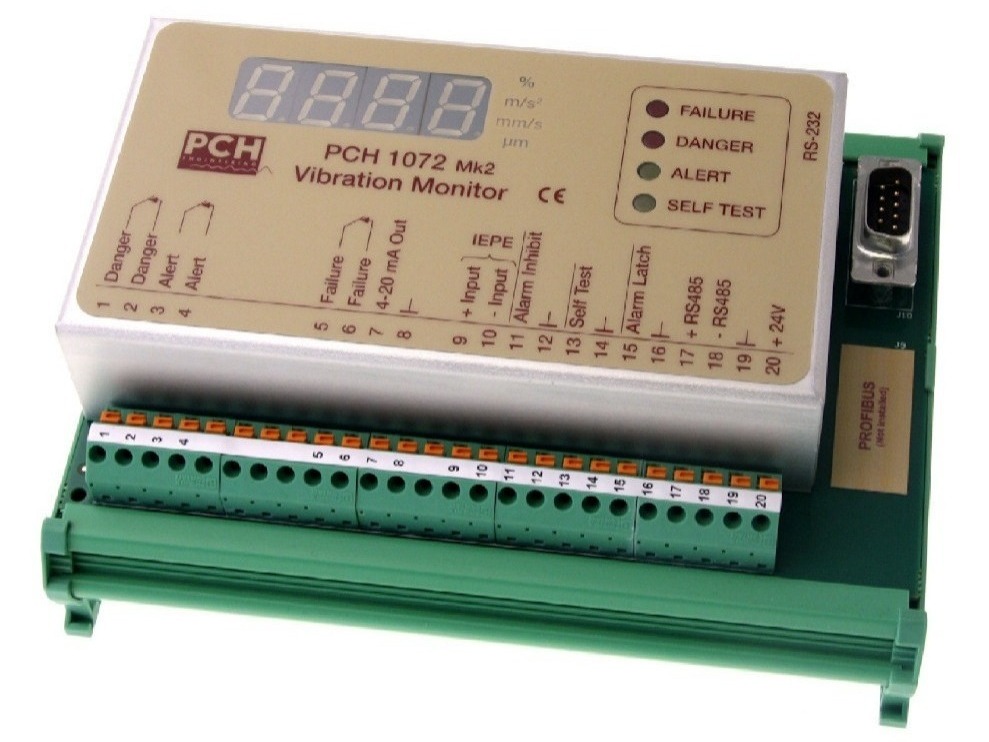

This advanced vibration monitor gives you thorough insights into the condition of your machinery. It is part of the modular condition monitoring system PCH Link Concept.

PCH 1072 has one input channel and two relays, providing SIL 2 machine protection. It measures acceleration, velocity or displacement.

PCH 1232

PCH 1232This vibration monitor uses several narrow filter bands to enhance vibration monitoring for condition monitoring purposes.

PCH 1272

PCH 1272This simple monitor is ideal as part of the safety chain for dangerous machinery when high accuracy and fast response time are important.

PCH 1277

PCH 1277This compact, ATEX certified vibration sensor with SIL 2 relays provides early warning of misalignment or bearing faults in machines in hazardous areas.

Predictive maintenance and Smart Factory technology are important tools in the digital transformation of the manufacturing industry.

At the same time, we know that local, SIL-level safety is a high priority for many of our clients.

With the PCH Cloud Solution, you can collect vibration data and access it online for remote trend mining and analyses.

At the same time, the real-time vibration and process data, local alarms, shutdown functions and redundant relays of the PCH vibration monitors provide local SIL-level safety, protecting your machinery and your staff from machine breakdowns.

We continue to monitor the measurements remotely, and it is a great foundation for the dialogue with our customer about setting threshold values for alarms.

Anders Lykkegaard, Development Engineer at Universal Bar Feeder ApS

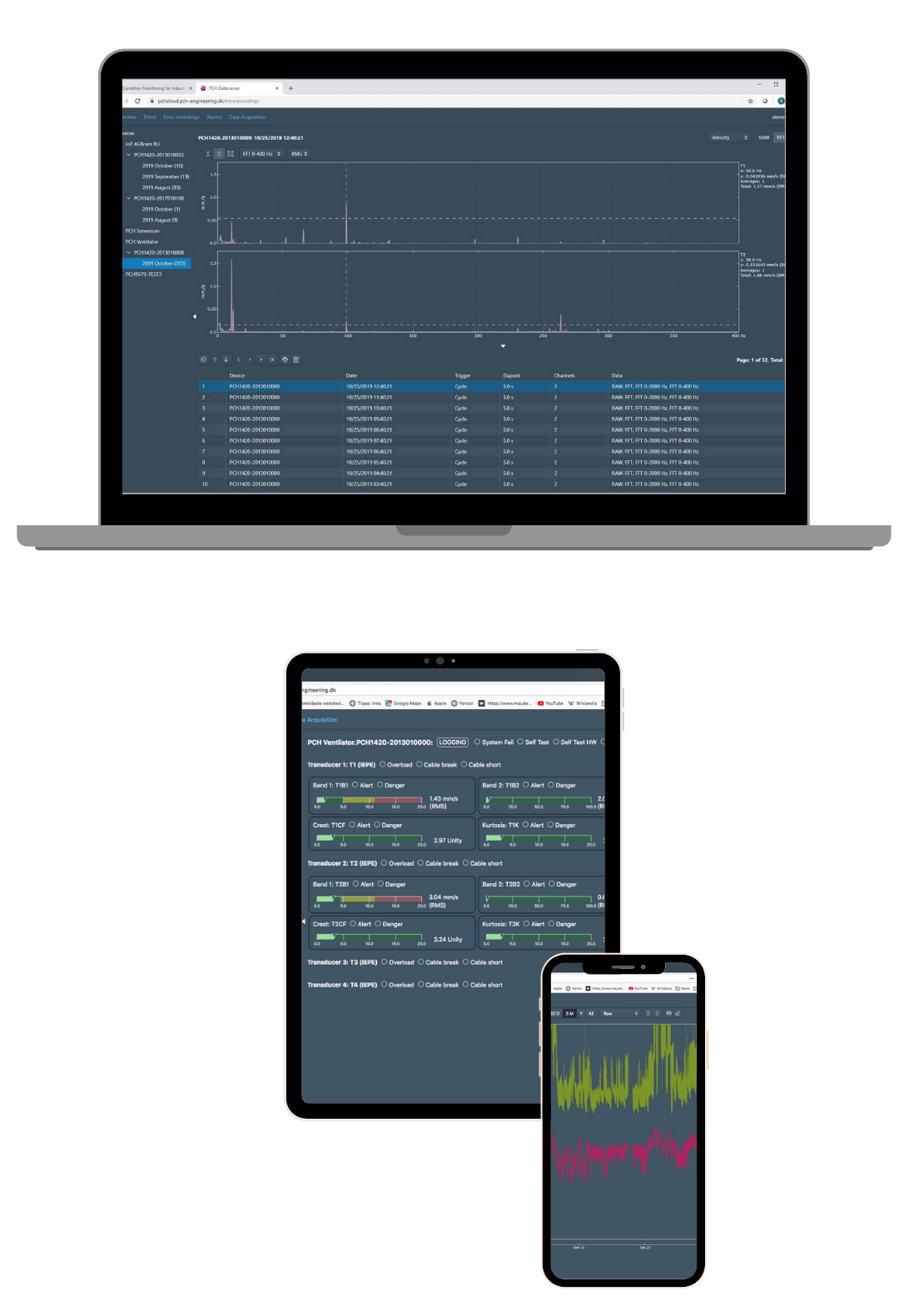

You can access your vibration and process data anywhere from any device.

On-site staff can easily check the current condition of each machine from their phone or tablet.

Your predictive maintenance crew or data analysts can track and analyse the performance and condition of machinery in various locations from the comfort of the office.

The real-time vibration data collected by the PCH vibration sensors is safely stored in PCH Engineering's AWS cloud database or a database of your choice.

You can access the PCH database and its visualisation tools from any internet browser, making centralised handling of data simple and secure.

It is also easy to share vibration data with external vibration specialists or service teams.

PCH Cloud comes with a mobile condition monitoring interface which enables quick asset health checks and on-site machine troubleshooting.

By scanning a QR code attached to the asset you wish to examine, you are directed straight to PCH Cloud’s visualisation of that asset’s vibration data.

You can also select assets from a simple drop down menu.

Looking at this site on your PC? Scan the QR code in the image with your smartphone camera.

Looking at the site on your phone? Tab here or tab the image above to access our test site.

Contact one of our expert consultants for more information on how the PCH Cloud Solution can help protect your machinery.

PCH Engineering

We are an experienced, ISO 9001 certified engineering company manufacturing standard orders as well as customised vibration monitoring solutions at our factory in Denmark.

Whether you are a machine owner, an OEM or a distributor we strive to be the best partner for you in machine protection matters.

We work fast, we are flexible and reliable, and we are financially strong.

Our products are manufactured in Denmark and follow all the necessary international production standards, regulatory standards and quality standards.

PCH Engineering A/S: Sales

Connect with us on LinkedIn.

© Copyright 2020 PCH Engineering A/S